ANL Packaging’s products are designed to streamline your supply chain by optimizing your production flow. All of our packaging is created to offer consumer convenience by following rigid guidelines that ensure food safe products.

By starting from the shelf and working backwards, we’re able to offer unique insights into consumer behavior to increase the impact at the point of sale.

Our vertical integration allows for full knowledge and guidance as your packaging progresses through the various stages and moves towards your tailored packaging solution.

- R&D

- Mould making

- Extrusion and recycling

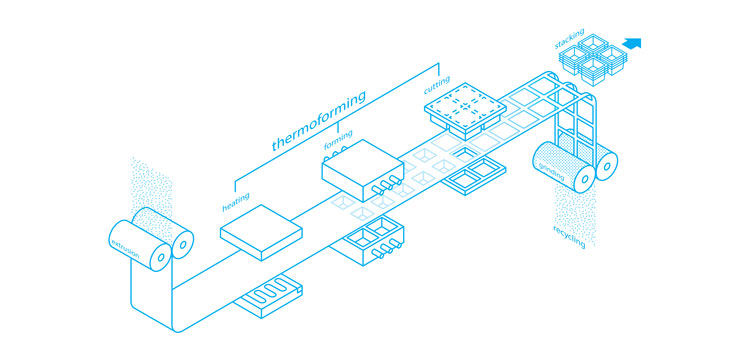

- Thermoforming

- Storage

Our focus

Reducing the impact of our production processes and aiming for sustainability across our entire manufacturing chain.

That starts with designing your product in a way that reduces the use of plastic while maintaining the integrity of the packaging. We don’t start manufacturing your packaging after a thorough prototyping phase that ensures your packaging has no faults.

All of our plastic contains 30% of recycled plastic. (PET contains 30% PCW, PP contains between 35% and 50% PIW). During our thermoforming process we immediately recover our surplus and recycle it.